SEE Electrical Harness Manufacturing

Um pacote de software inovador para a fabricação de chicotes elétricoss.

A complete set of modules with advanced features

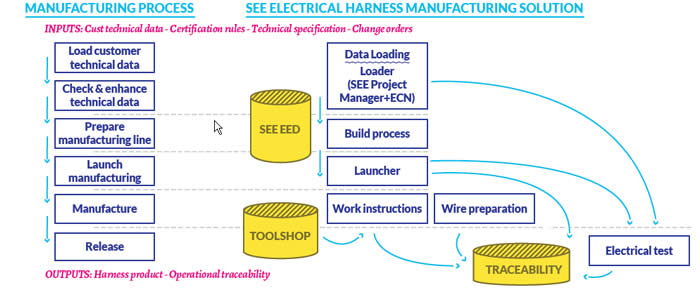

- Manufacturing engineering phase

Starting with data representing the physical harness (eg. customer data in XML format), this set of tools will prepare harness manufacturing data. First step is to load the data (effectivity and legacy management). Then, ECN applies automated changes, executes custom rules and checks physical harness data. Hence, Build process assigns operations and tools, sorts wires and assigns the different helps. The output is an industrialized harness. - Production phase

Launcher generates the manufacturing harness by worksite as well as the differential.

A set of independent modules provides added features

- Wire preparation: creates production batches, assigns machines and printers, cuts cables/protections and prints labels.

- Work instructions: designs templates and generates static instructions as well as interactive instructions (Apple, Android or Windows apps).

- Test: assigns mating and interfaces, calculates functional lines, maps addresses and generates tester code.

- Traceability: stores production traceability, validates harness production and provides after-delivery inspection.

- Toolshop: manages tools, tools revisions and tools authorizations.

- Workers and Skills: manages operators as well as skills and trainings.

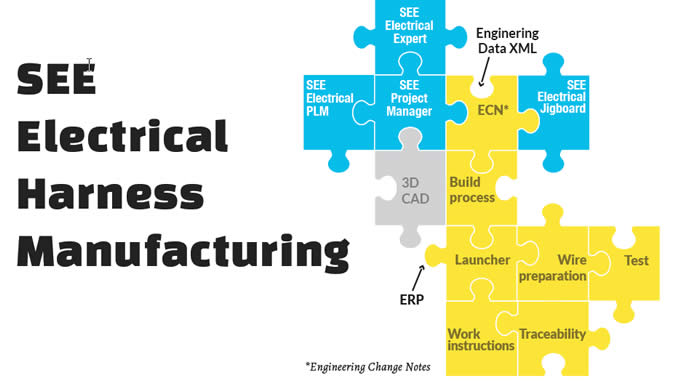

Easy integration with IGE+XAO tools

SEE Electrical Harness Manufacturing can be interfaced with several packages from IGE+ XAO and therefore provide

increased functionality. For instance, SEE Electrical Jigboard provides the scaled harness fl atenning for production

tables (form board/jig board). It takes into account all harness constraints such as branch diameters, wires routes and

bend radiuses. It also provides a set of additional functionalities (add curves, export devices, jig board locations…) SEE

Electrical Equipment Defi nition can also be used to store all the electrical equipment data.